Tattooing is an ancient art form, and over the years, people have crafted tattoo needles using various materials. The ancient Egyptians used metals like bronze, while other cultures sharpened bone, bamboo, and other objects to create long-lasting body art. Today, needles are often made of two stainless steel grades: 304 and 316. This post will discuss why they're used for crafting the different types of tattoo needles on the market and why Grip Needles prefers stainless steel 316.

Steel that Doesn't Corrode

Steel is one of the toughest artificial materials ever and is made by combining iron and carbon. However, it can gradually lose its durability because of corrosion. During the early 20th century, scientists and metallurgists discovered that adding metals like chromium to steel could increase its corrosion resistance, creating stainless steel.

Over the succeeding decades, further changes to the alloy's composition led to the invention of different stainless steel grades like 304 and 316. For example, 304 stainless steel is made by adding chromium and nickel to steel, while 316 results from adding chromium, nickel, and molybdenum.

Different compositions, different traits

The differences in the composition of 304 and 316 stainless steel also result in different characteristics. For one, even though both grades are corrosion-resistant, 316 stainless steel is less likely to degrade by exposure to chlorides and acids. This means it can last longer even when continuously exposed to harsh, acidic environments.

An alloy's composition can also affect its price. Because it contains one more metal than grade 304, 316 stainless steel is usually more expensive. However, its superior resistance and extra durability make it worth its higher price tag.

Ideal for professional tattoo needles

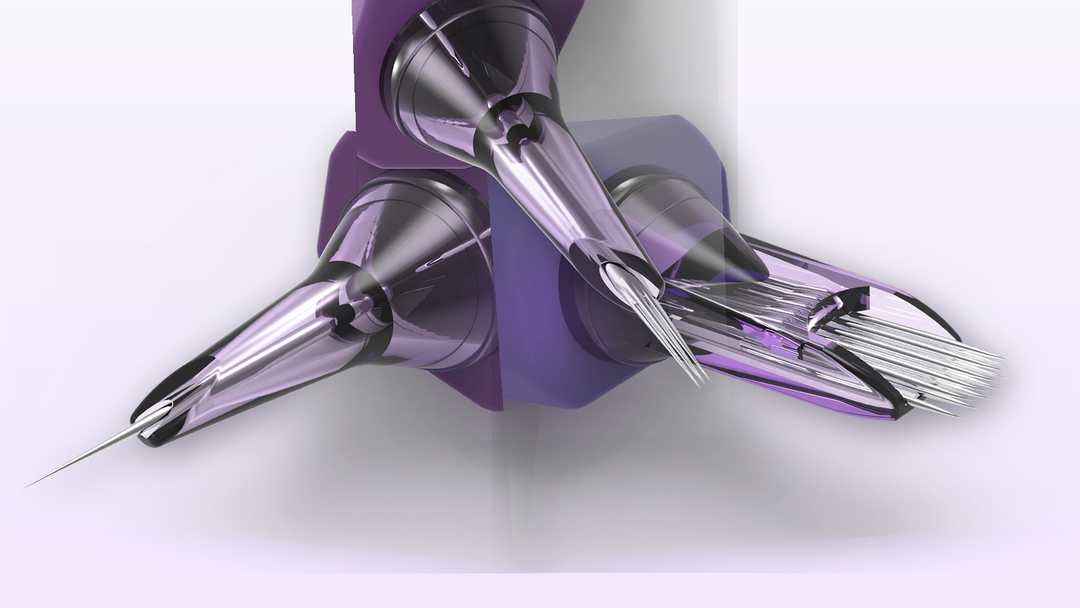

Some manufacturers use 304 stainless steel to make professional tattoo needles. However, Grip Needles' TriFlat™ needles and other products are made from 316 stainless steel, and there are several compelling reasons for this choice.

The various tattoo needles used in body art and permanent makeup (PMU) all come in direct contact with the client's body, so they must undergo a thorough sterilization process. This keeps them clean and prevents cross-contamination, which can spread dangerous diseases. Tattoo needles made from 316 stainless steel can withstand the strong chemicals and intense temperatures used to eradicate pathogens during sterilization.

Their superior corrosion resistance also means 316 stainless steel tattoo needles maintain their integrity even after exposure to substances like certain acids in the tattoo ink. This means they are not likely to lose their sharpness and durability over time.

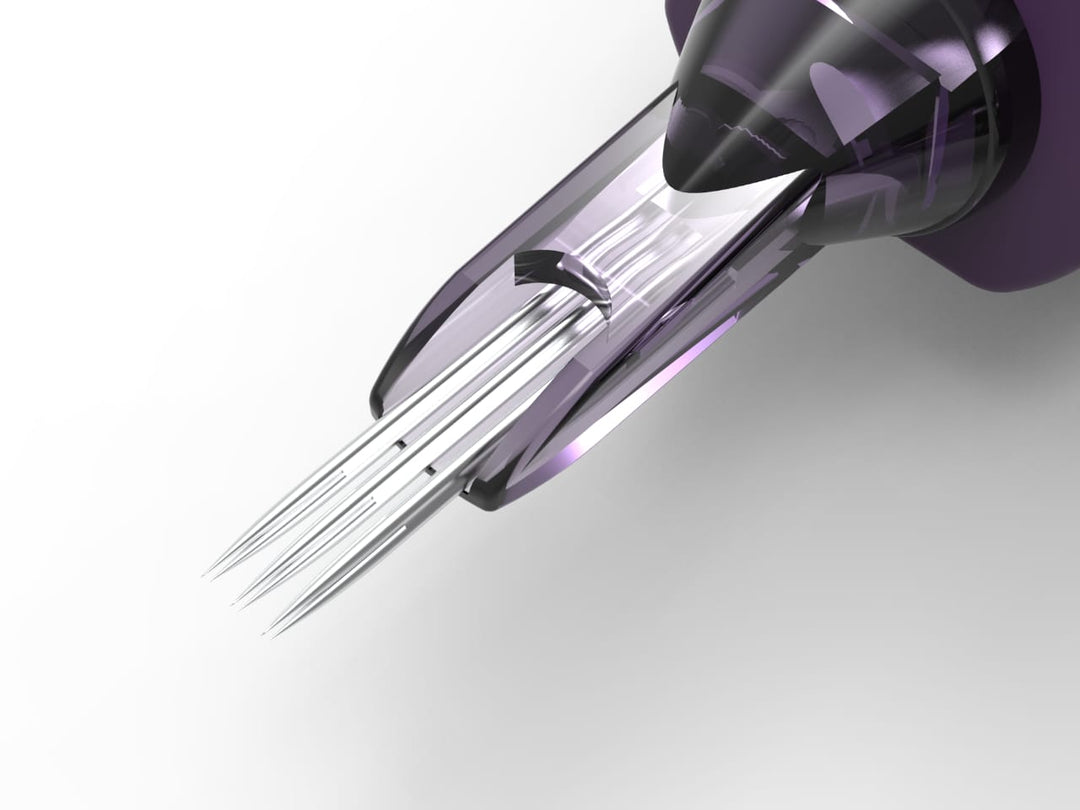

Furthermore, 316 stainless steel needles tend to remain sharp longer than needles made using grade 304. This is important because blunt needles deposit pigment less efficiently and cause more trauma to the client’s skin. Sharper needles help tattoo artists make more precise patterns and cause less discomfort to clients.

Needle sharpness can also affect an artist’s efficiency. When a needle becomes blunt, artists have to replace it with a new, sharper one. Although changing needles has become easier thanks to needle cartridges, doing so midway through one’s work several times can still be disruptive and costlier. Using needles that remain sharp longer means artists finish their work in less time.

On the downside, 316 stainless steel is so tough that it often requires specific tools to machine well, making it more difficult to manufacture products with it. This increases the price tag on 316 stainless steel products, but the benefits far outweigh the cost.

Each of Grip Needles' products is designed and built for the safety of artists and their clients. Whether it's hybrid or 3RL needle cartridges, every item is constructed from medical-grade plastic and surgical 316 stainless steel. With this combination, tattoo and PMU artists are assured of the highest-quality needles that have passed strict safety standards.

Grade 316 stainless steel is strong, durable, and can withstand a wide variety of substances and conditions. These characteristics make it the ideal material for making superior tattoo needles that are safe and can deliver precise and exceptional results. Get the highest-quality tattoo needle cartridges at Grip Needles today!