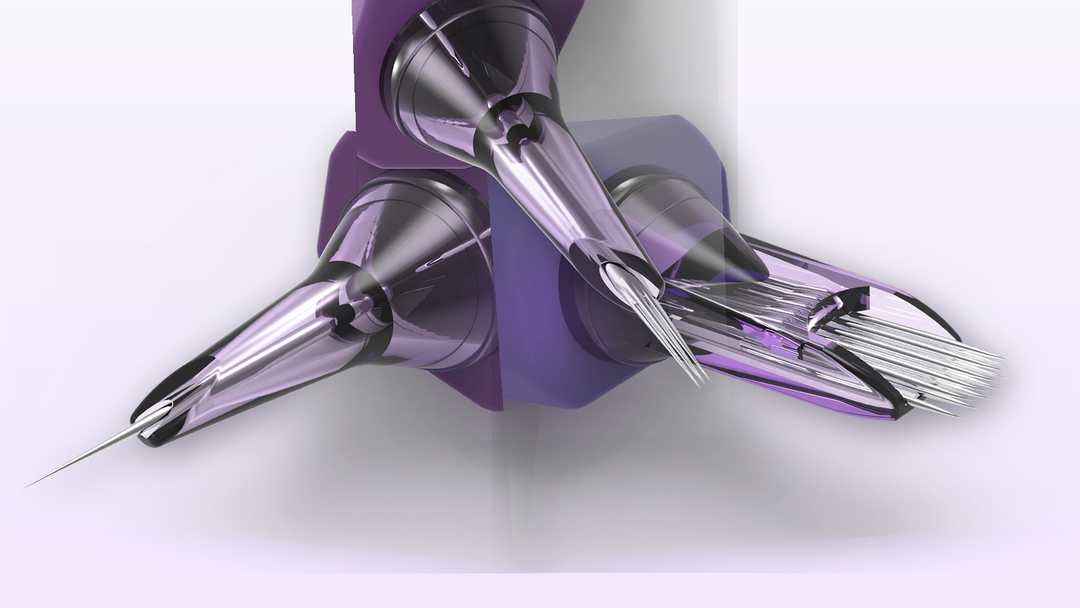

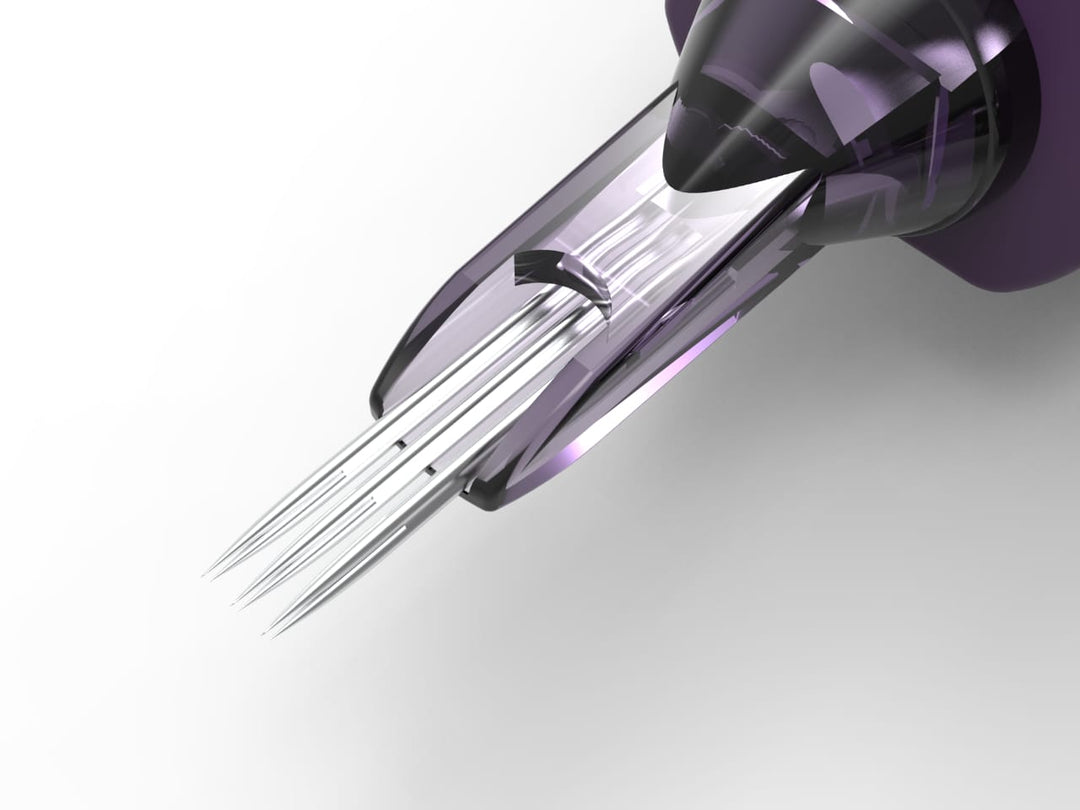

Tattoo needle cartridges are a truly revolutionary invention, enabling tattoo and permanent makeup (PMU) artists to quickly and safely change needles as needed. Just pop the cartridge into your tattoo machine, and you're ready to go. Thanks to these cartridges, tattooing has become more efficient and safer for artists and clients.

The plastic housing that encases the stainless steel tattoo needle is one of the key components of any needle cartridge. It's so important that it should not be made from just any type of plastic. The best-quality tattoo needle cartridges are usually made from medical-grade plastics, and there are several good reasons why.

A Special Type of Polymer

Medical-grade plastics are polymers created specifically to meet stringent medical requirements. They possess properties that make them ideal for healthcare applications, including:

-

Bio-compatibility. Certain resins and plastics can cause irritation and allergic reactions in some people. Medical-grade plastics do not produce toxic or immune responses when they come in contact with the body or bodily fluids.

-

Sterilization compatibility. Some sterilization methods use high temperatures and chemicals that may warp or degrade regular plastic. Medical-grade plastics can withstand and do not degrade when sterilized through approaches like autoclaving and ethylene oxide (EO) gas.

-

Non-permeability. Regular plastics may have microscopic pores that harbor microbes or permit the transmission of fluids. Medical-grade plastics prevent fluids and bacteria from passing through and getting absorbed or transmitted, helping avoid cross-contamination.

-

Durability. Over time and after exposure to harsh conditions, regular plastics may warp, chip, or lose their integrity. Medical-grade plastics are strong and resilient, maintaining their shape and sturdiness even after exposure to harsh substances.

- Regulatory compliance. Medical-grade plastics must comply with stringent FDA regulations and ISO standards to ensure their safety, compatibility with their intended usage, and material composition.

As their name suggests, medical-grade plastics are extensively used in healthcare settings. They are in everything from medical machinery and surgical equipment to implants and prosthetics, to containers, tubes, and even clothing. However, you may have encountered them in everyday objects like food packaging, kitchenware, sports equipment, toys, and electronics.

There are different types of medical-grade plastics, including polystyrene (PS), polypropylene (PP), and polycarbonate (PC). The housing on Grip Needles' disposable tattoo needle cartridges is constructed from medical-grade PC, known for resistance to impacts, chemicals, and high temperatures.

In the Name of Safety and Quality

Medical-grade plastics are indispensable for making high-quality and safe tattoo needle cartridges, including Grip Needles' premium 3RL tattoo needles. This means that with every product from Grip Needles, you are assured of:

Enhanced Safety and Hygiene

All needle cartridge components, including the plastic housing, are sterilized using EO gas to eliminate all disease-causing pathogens. The cartridges are then individually packed to ensure they remain sterile until use. This process guarantees the utmost hygiene and safety for both artists and clients. What's more, the impermeability of the plastic housing prevents cross-contamination that might result in allergic reactions and bloodborne infections.

Reliable Performance

Tattoo machine cartridges do not necessarily get used immediately after being manufactured. Sometimes, it might take months before they're taken out of their packaging. Therefore, they must remain durable and maintain their shape over time and after exposure to sterilization. When you take a Grip Needles cartridge out of its packaging, you can be sure the plastic casing is as sturdy as new and will not break during use.

Greater Comfort and Precision

Grip Needles considers artists' comfort when designing and manufacturing needle cartridges, and this is shown in some of their products' features. The removable silicone sleeve on each cartridge, meant to reduce finger fatigue, especially during big and time-consuming projects, is a good example. Using a medical-grade PC for the housing reflects this, too, as the material's durability means you can confidently grip and maneuver the cartridge without worrying that it will bend or break.

Additionally, medical-grade plastics are famously lightweight. After all, surgeons and healthcare staff must be dexterous during medical procedures, so their tools must be light and not cumbersome. Similarly, tattoo artists must have a steady hand and control to create precise lines and shading. With Grip Needles' medical-grade PC housing, you get a durable but light cartridge that's easy to maneuver.

Increased Client Satisfaction

A safe and high-quality tattoo needle cartridge can help you create masterpieces that your clients will love. It also enables you to capture their trust and give them a pleasant experience throughout the tattooing process. They don't have to worry about adverse reactions, leaving the procedure feeling satisfied and more likely to come back for future sessions.

Medical-grade plastic is one of the best and most reliable materials for high-performance tattoo needle cartridges, thanks to its superior durability, safety, and biocompatibility. Its use in Grip Needles' products speaks of the company's commitment to creating safe and comfortable products that help artists effectively and efficiently create artworks that express their creativity and satisfy clients. Start creating masterpieces with Grip Needles today!

Do you want to learn more about medical-grade plastic? Here’s everything you need to know about this revolutionary material.